[ad_1]

In a landfill, a plastic bottle can take greater than a thousand years to interrupt down. However a brand new course of can remodel PET plastic in days, utilizing micro organism to eat the waste after which flip it right into a biodegradable materials impressed by spider silk.

The system, developed by researchers at Rensselaer Polytechnic Institute (RPI), is designed to deal with two issues—each having to cope with present plastic waste and the best way to make new supplies which can be extra sustainable. Of the hundreds of millions of tons of plastic produced globally yearly, the overwhelming majority isn’t recycled. PET plastic, present in single-use meals packaging, is particularly prone to find yourself in landfills or the setting, degrading into tiny items that may find yourself in beer and breast milk. Producing new plastic from fossil fuels additionally has a huge carbon footprint and provides to the pile of waste.

[Photo: RPI/Dakota Pace]

To develop the brand new method, the scientists turned to micro organism which can be naturally capable of devour polyethylene. Then they genetically edited the microbes in order that they might additionally produce a silk-like materials, by inserting a sequence of amino acids just like a protein present in silk.

“What we’re utilizing is a course of that’s similar to brewing beer,” says Helen Zha, an assistant professor of chemical and organic engineering at RPI and one of many authors of a brand new paper in regards to the venture. “It’s primarily fermentation.” As a substitute of feeding the microbes sugar, like a brewery would, the researchers feed them a “predigested” type of plastic waste that’s been heated beneath stress. When the micro organism eat the plastic, they use the carbon in it to make the brand new materials.

[Photo: RPI/Dakota Pace]

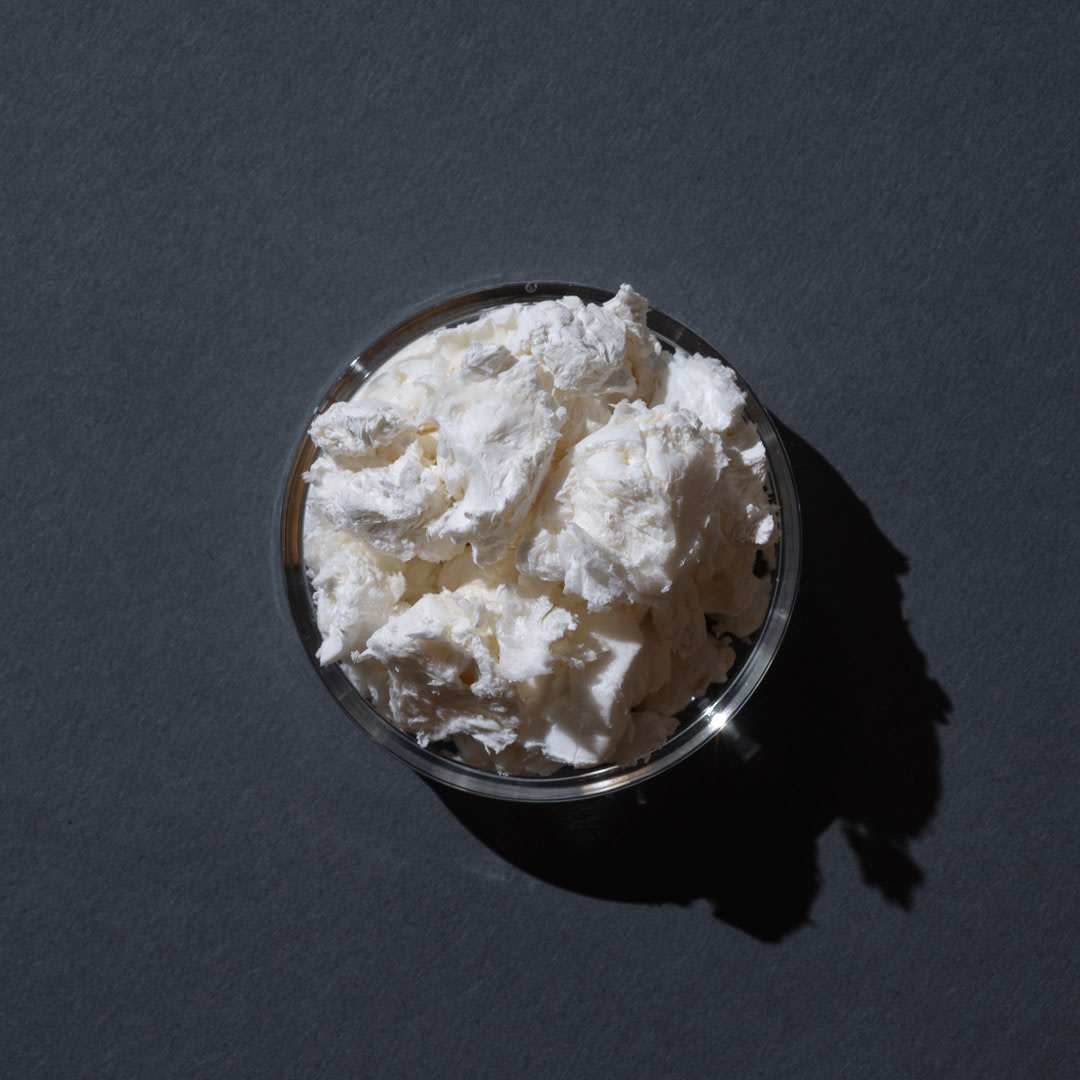

The identical course of may very well be used to make different supplies, however the scientists wished to start with silk due to its distinctive properties: Silk will be each very sturdy and light-weight, and it’s naturally biodegradable. “It features like a plastic that we’re used to, in some ways, and it additionally breaks down very naturally even when we don’t deal with it in some particular method,” she says. “We don’t have to fret about microplastics from silk, or Pacific rubbish islands floating round with silk.”

Pure silk is already utilized in some purposes past material, together with as an ingredient in skincare merchandise or to make medical merchandise like surgical dressings. However the conventional manufacturing course of isn’t sustainable, because it entails plenty of land, water, and fertilizer to develop meals for silkworms. (It additionally isn’t vegan, because the silkworms are killed.) It may’t scale up simply, because it takes time to boost the silkworms and for them to supply cocoons. Spiders aren’t farmed for silk as a result of the method can be even much less environment friendly.

If silk have been brewed from plastic as a substitute, it might probably be used extra broadly, making gadgets like plastic wrap, which might’t be simply recycled now. “It’s a protein, so you could possibly really eat it if you wish to,” says Zha. If it ended up in a landfill or littered in nature, it might break down, not like some types of “biodegradable” plastic that degrade much more slowly in the event that they’re not processed in an industrial-composting facility.

Utilizing gene modifying signifies that it’s additionally potential to regulate the fabric, trying to inspiration from the sorts of silks made by several types of spiders (a single spider by itself could make seven several types of silk). “One of many advantages of working with an engineered organism versus an precise spider or an precise silkworm is we are able to management very exactly the amino acid sequence of the protein that we make,” Zha says. “And which means we are able to additionally begin to management and tune the properties of the ensuing materials.” A silk ingredient utilized in cosmetics may be engineered to carry onto water and break down simply, for instance, and silk used to make a nylon-like materials for clothes may be tweaked to be stretchier and longer-lasting.

Thus far, the scientists have demonstrated a proof of idea, displaying for the primary time that micro organism could make a worthwhile materials by feeding on plastic waste. Now, the workforce is working to make the method extra environment friendly in order that the micro organism can produce extra materials. Whereas it should take extra R&D, Zha says that she’s optimistic that the yields can enhance to the purpose the place manufacturing might turn out to be commercially viable.

Others are additionally engaged on methods to make use of biology to cope with plastic waste. Carbios, a French startup, uses an enzyme that was originally discovered eating PET plastic in compost, tweaking it so it may possibly break down plastic sooner at greater temperatures. After this “enzymatic recycling,” the molecules can be utilized to make new plastic in a closed loop. The corporate plans to open its first large-scale recycling plant subsequent yr.

However turning plastic right into a biodegradable materials, as a substitute, may very well be much more helpful. The fundamental method might assist remodel manufacturing. “As a substitute of huge chemical crops, with actually nasty chemical compounds and excessive temperatures making plastics for us,” says Zha, “nature might make the supplies we’d like with the properties we’d like, at pretty low temperatures. And that materials may very well be helpful, and never pollute the planet in the long run. To me, that’s the form of future that we must be striving for.”

[ad_2]

Source link