[ad_1]

Fujii Minoru and Sugimoto Hiroshi consider they will change the world one paint job at a time. These materials scientists at Kobe College have found a brand new substance that may cowl a floor with any vibrant coloration however use solely 10% of the load of conventional paint. As Sugimoto explains in a press launch, “We are able to apply it to the coating of, for instance, airplanes. The pigments and coatings on an airplane have a weight of a number of tons of of kilograms. If we use our nanosphere-based ink, we would be capable to cut back the load to lower than 10% of that.”

These nanospheres are almost-invisible silicon crystals that, in response to new analysis printed within the peer-reviewed journal ACS Applied Nano Materials, mirror mild in such a means that may cowl a full spectrum of vibrant, lasting colours.

On the coronary heart of their discovery is the straightforward scientific proven fact that coloration isn’t just about what mild is absorbed but additionally about what mild is mirrored. Conventional pigments work by swallowing sure wavelengths of sunshine, leaving us with the colours we see. Over time, although, these pigments tire, just like the design of a poster light by solar.

Nature reveals its true colours

Nature reveals us that there’s one other method to get hold of vibrant colours that persist by means of time, just like the iridescent sheen of a butterfly’s wing or the vivid plume of a peacock. That is known as structural coloration, which mainly manipulates mild on the nanometric stage to supply coloration.

That is the important thing to Fujii and Sugimoto’s breakthrough. Sugimoto says that the excessive reflectance of the nanosphere—regardless of the small protection of the floor—“is because of the very massive scattering effectivity” of those silicon nanocrystals. “The requirement of a really small quantity of silicon crystals for coloration is a bonus within the utility as a coloration pigment,” he says.

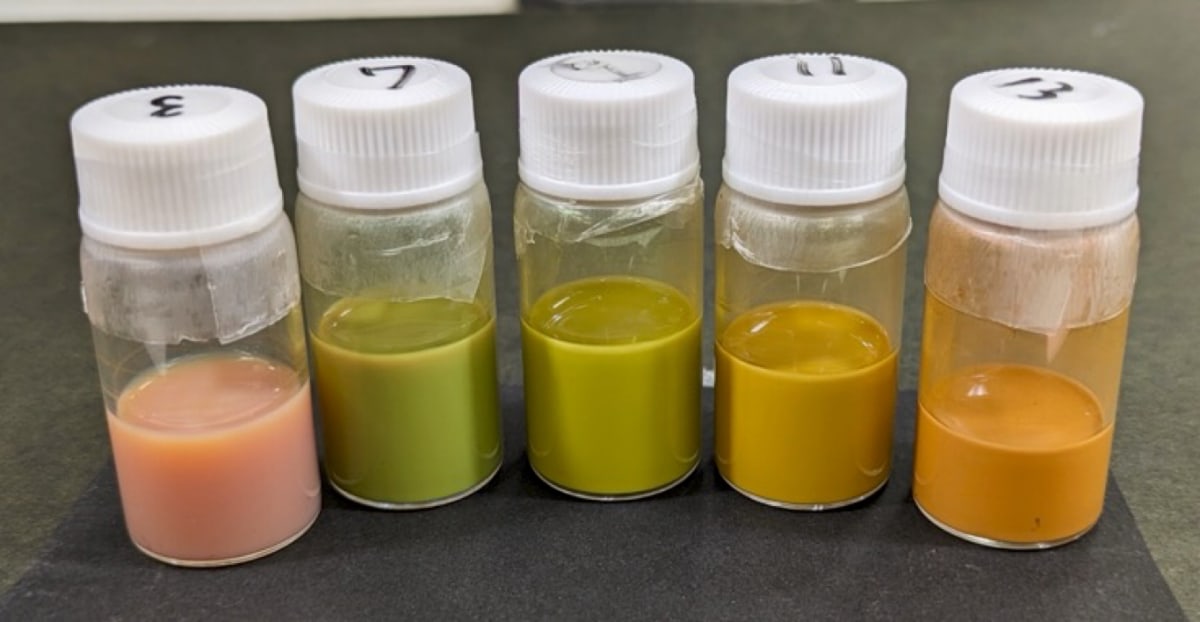

Fujii says that this work follows earlier analysis since 2020, once they first achieved the exact particle measurement management to acquire the precise measurement of nanocrystals they wished. Since then, the crew has developed “colloidal suspensions of spherical and crystalline silicon nanoparticles,” he says. Colloidal suspension is what makes the precise paint, mainly a steady state during which the nanoparticles stay combined with the liquid that helps them, with out separating. This can be a essential requirement to create usable paints.

[Photo: Fujii Minoru]

The nanoparticles, they clarify, generate coloration scattering mild by means of a phenomenon known as Mie resonance. “[This] permits us to develop structural coloration inks,” Fujii explains. Simply how an audio engineer can management the pitch of a notice by altering the form of the waves, the crew can shift the colour these nanocrystals mirror by manipulating their measurement. Smaller particles produce blues and violets, whereas bigger ones mirror vibrant reds and oranges.

However the true magic of their invention, they are saying, is the consistency of the colour. Whereas conventional structural colours like these displayed by some animals change relying in your viewpoint, these silicon nanospheres hold the identical coloration from any angle.

[Photo: Fujii Minoru]

The load of the matter

The benefits of the invention don’t finish of their brightness, sturdiness, or consistency. The low weight is the most important issue that may save a lot cash in so many industries. Because the researchers clarify: “A single layer of sparsely distributed silicon nanoparticles with a thickness of solely 100 to 200 nanometers reveals vibrant colours however weighs lower than half a gram per sq. meter.”

The reason being that these nanospheres have an excessive light-scattering effectivity. Which means they shine brightest once they stand aside, so that they don’t require as a lot density as conventional pigments.

Contemplate the implications in an business like aeronautics, the place each single ounce on a aircraft, even a sugar packet to your espresso, has an effect on fuel consumption. If you multiply the load of one thing tiny like a sugar packet by the variety of models of that factor inside a aircraft by the variety of airplanes with sugar packets by the variety of flight hours, quickly you find yourself with hundreds of thousands of kilos of gas spent worldwide so you may have candy espresso inflight.

Now think about the load of the paint overlaying an airplane. It could appear insignificant, however the impact may be staggering to each the price of the flight and the hundreds of thousands of tons of CO2 produced.

The paint on an plane, whereas important for cover and branding, isn’t just a layer of coloration. It have to be lifted with each takeoff, carried by means of each mile, and introduced again to earth with each touchdown. Contemplate your typical Boeing 777, one of the vital well-liked wide-body airplanes on the planet. Utilizing this new nanoparticle paint, every 777 would shed 450 kilograms. That’s the load of a grand piano in paint alone.

Whereas this would possibly sound trivial for a machine that weighs greater than 300 tons, take into account the larger image. In the middle of a 12 months, a typical 777 consumes about 168,750,000 kilograms of gas. With this new nanoparticle paint, every plane would save nearly 76,000 kilograms of gas yearly. This interprets into a discount of roughly 239.2 metric tons of CO2 per aircraft per 12 months.

Now think about a provider with 100 777s in operation. Yearly, this fleet may save about 7,593,750 kilograms of gas, translating to a CO2 discount of about 23,920 metric tons. If we peg the worth of aviation gas at round 80 cents per kilogram, the financial savings quantity to roughly $75,937.50 per plane per 12 months. For our hypothetical fleet of 100 planes, this accumulates to a whopping $7.59 million in annual financial savings.

However let’s zoom out additional, to the skies of the US, dwelling to 1000’s of business plane. If even a fraction of those planes adopted the expertise, the financial savings in gas prices and CO2 emissions could be monumental. We’re speaking hundreds of thousands of {dollars} saved and tens of 1000’s of metric tons of CO2 averted yearly.

Globally, the affect may scale even greater. With greater than 20,000 industrial plane within the skies worldwide, the adoption of nanoparticle paint may translate into financial savings of tons of of hundreds of thousands of {dollars} and a big stride towards a greener, extra sustainable future in aviation. For an business already obsessive about saving each single pound to avoid wasting each doable penny, this paint will undoubtedly be a gorgeous proposition. Now we have to see it evolve into an actual industrial product that may be utilized on airplanes—and in all places else.

[ad_2]

Source link