[ad_1]

It’s a very impractical method to make a pair of denims. However that’s what makes MTTR—a brand new British model based by denim business professional Bob Shankly, that includes designs by Mohsin Sajid, who Shankly dubs “the Jony Ive of denim”—so refreshing.

To wit, listed below are their plans, which might trigger the C-suites of any main clothes firm to recoil in horror:

—MTTR’s denims are restricted to 500 pairs per 12 months—the quantity the model must hold the lights on, and nothing extra.

—There aren’t any plans for progress.

—While you order a pair, you’ll need to click on by means of a “Assume earlier than you buy” button with a built-in delay to forestall impulse buys.

—MTTR pockets 20% of the 170 pound ($215-plus) denims, which matches towards operating the corporate. The remainder is the price of making the denims.

—They aspire to be the second-most accountable denim firm on the planet. As Shankly places it, “probably the most accountable is the pair of denims that you just don’t purchase.”

All of this would possibly seem to be an idealist’s fantasy (admirable, albeit in poor health fated) had been it not for the folks concerned, like passionate denim business professional Shankly, who beforehand labored for the cult-favorite Welsh model Hiut earlier than launching MTTR.

[Photo: MTTR]

“The query I’d at all times ask myself is, ‘Does the world want extra denims?’ And naturally, the reply is not any,” Shankly says. “However then I in all probability began to ask myself the unsuitable query, which was, ‘In the event you had been going to make one thing the world doesn’t want, how would you make a distinction?’”

For Shankly, it meant fully reimagining the way in which trendy denim is made. Shankly and Sajid started by reversing the design course of: If the final word objective was to create a pair of recyclable and repairable denims, how would they get there? Materials, in fact, was essential. After working with a well-established denim maker on a material created from wooden pulp and recycled cotton—with no pesticide use, no water, no wasted vitality and chemical substances—they thought that they had discovered their match. However then on the eleventh hour the corporate added in a little bit of virgin cotton. And MTTR fully pulled out, successfully returning to sq. one.

[Photo: MTTR]

“The only-mindedness of Bob’s considering in the entire venture is admittedly key,” says MTTR founding associate Jim Sutherland (the designer accountable for the superb no-waste minimalist design of MTTR’s web site). “For me, that was only a actually seminal second.”

As luck would have it, Sajid had been speaking to Cone Denim a couple of new product the corporate was launching, dubbed Bonzai—a 100% fully recycled cotton. Virtually 24 hours after dropping their cloth, that they had a brand new one, which MTTR could be the primary to make use of.

[Photo: MTTR]

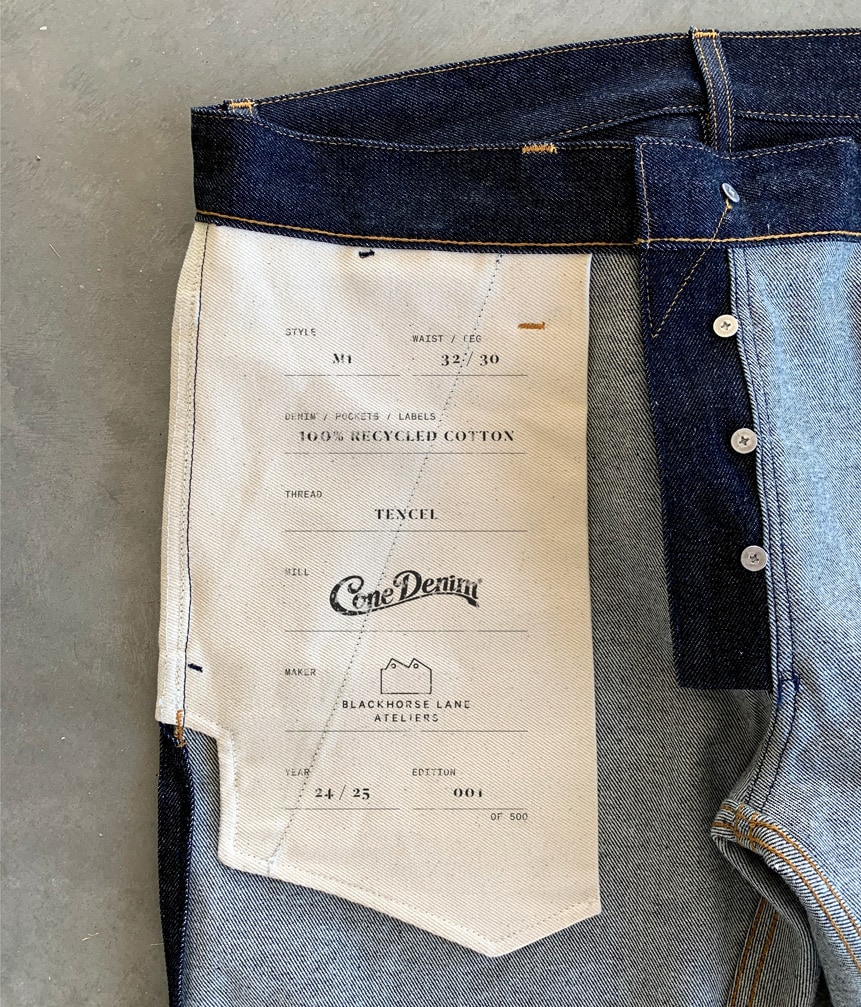

Nonetheless, the search for recyclable denims goes far past cloth. Shankly says that when denims hit a recycling facility, solely the back and front of the leg space are lower away and recycled; the opposite 40% winds up in a landfill or incinerator because of the rivets, leather-based model patches, and labels that aren’t recyclable. Seams with thread additionally usually don’t make the lower as a result of employees don’t have any method of understanding what they’re produced from. Thus MTTR’s denims don’t have any leather-based patch, however characteristic a clearly labeled pocket bag itemizing the composition of their supplies, that are all recyclable (and which MTTR will recycle for purchasers; all they need to do is ship the denims again on the finish of their life cycle).

[Photo: MTTR]

One other huge problem: the button on the denims’ waistband. After struggling to discover a associate that would present a removable button (“that’s actually why the jean hasn’t modified in 150 years—as a result of it’s such a longtime course of,” Shankly says), the crew discovered one 150 years up to now. “Bachelor buttons” had been initially created for solo males to make DIY fixes to their garments within the nineteenth century, and MTTR is resurrecting “Pilcher’s Automated Bachelor Button,” which might simply be eliminated and reused or recycled.

[Photo: MTTR]

Ultimately, MTTR emerged with the M1, named for Mohsin Sajid. And the final product was checked in opposition to Dieter Rams’s 10 ideas of excellent design—which is probably apt, as documentarian Gary Hustwit (director of Rams and Helvetica) as soon as noted, “If Dieter Rams began a denim model, it’d in all probability be one thing like MTTR.”

After intensive fit-testing and fine-tuning, the primary 100 pairs of the M1 have now gone into manufacturing at Blackhorse Lane Ateliers in London, and Shankly expects to launch a public wave round Could.

Past denims, although, he says what he’s actually promoting is an concept. You might even see insanity in his plan—however he sees the way forward for denim. “It’s values,” he says. “You’re in a position to put on your values. And on the very primary stage, that’s what vogue is about, isn’t it?”

[ad_2]

Source link